X CarbonTech

At X CarbonTech, we design and produce high-performance carbon fiber components and composite structures for the industries of the future. From CNC machining and resin infusion manufacturing to custom sandwich panels and 3D prototyping, we deliver precision, strength, and innovation in every detail. Partner with us for European-quality carbon fiber production trusted by aerospace, automotive, and industrial clients across the world.

Professional & Technical

Explore our work — from custom carbon fiber components to full composite assemblies. Every piece is engineered for strength, accuracy, and performance that meet global standards.

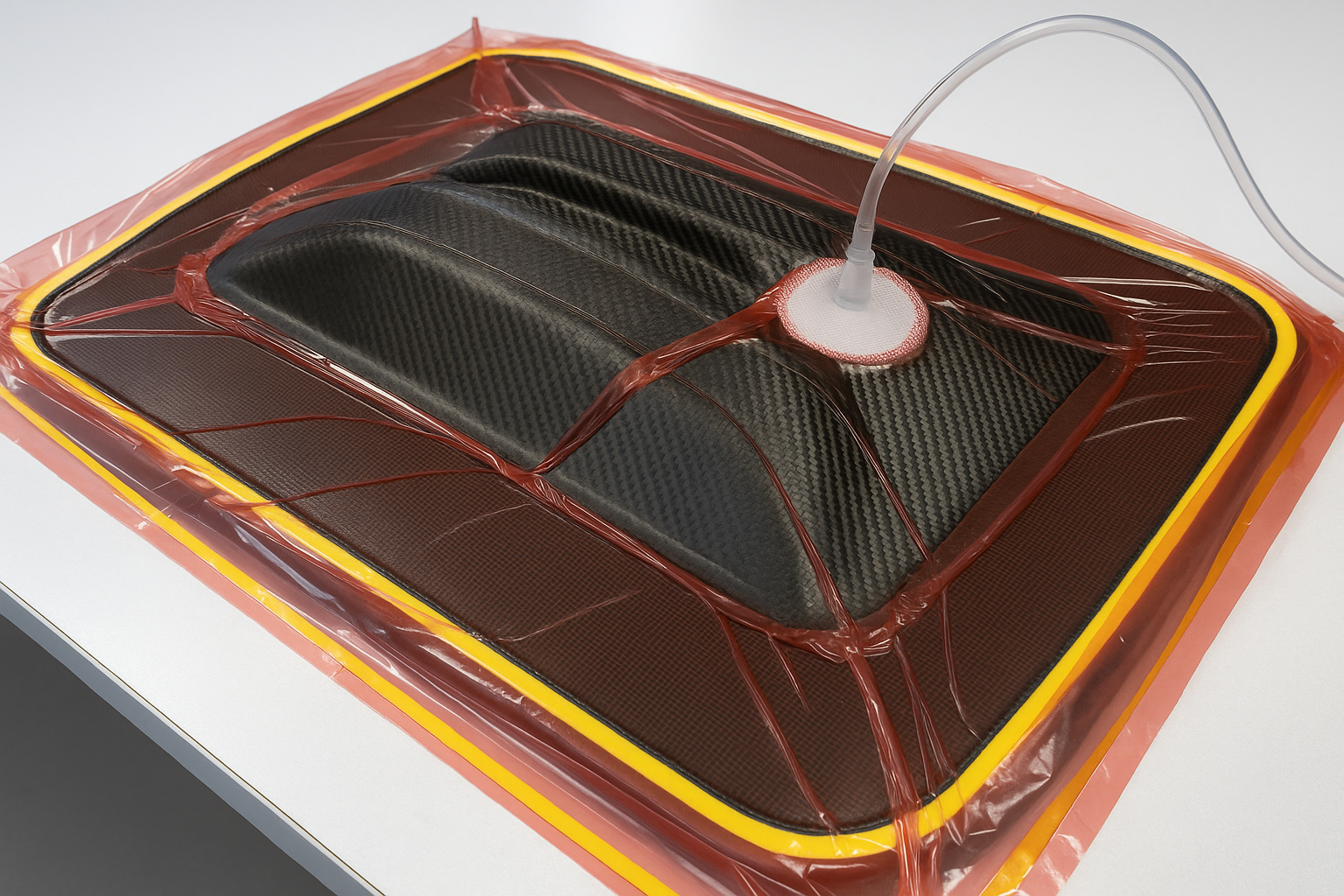

Carbon Infusion Technology

Professional-grade carbon infusion process for strong and lightweight composite parts.

Composite Products & Technologies

From precision-engineered carbon fiber parts to advanced sandwich structures — explore the materials and processes behind our composites.

Sandwich Panels

Lightweight carbon sandwich panels with PMI or honeycomb cores for stiffness and low weight.

Sandwich Panels

Carbon Fiber Tubes

High-strength carbon tubes built for drones, machinery, and lightweight frames.

Carbon Fiber Tubes

Carbon Plates

Rigid laminated carbon fiber plates for precision and visual applications.

Carbon Plates

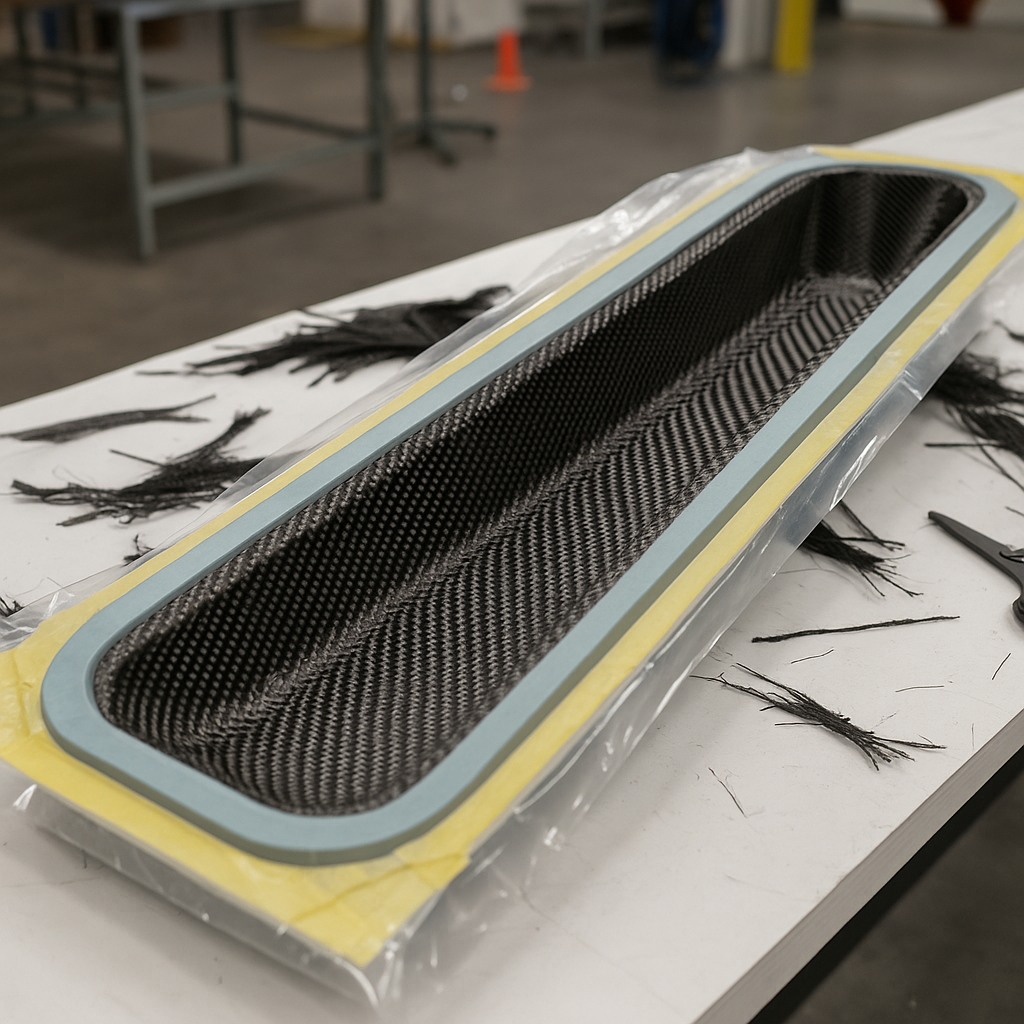

Infusion Process Components

Carbon fiber parts manufactured using advanced vacuum infusion techniques.

Infusion Process Components

Carbon Fiber Fabrics

Base reinforcement used across all our composites, available in multiple weights and weaves.

Carbon Fiber Fabrics

Aramid & Hybrid Fabrics

Kevlar and hybrid carbon fabrics for added toughness and impact resistance.

Aramid & Hybrid Fabrics

Why Choose Us

Precision, performance, and passion — the foundation of every carbon fiber part we build.

Manufacturing Excellence

Our production combines cutting-edge technology with expert craftsmanship. From resin infusion and mold manufacturing to CNC finishing, every step is controlled for accuracy, repeatability, and visual perfection. We ensure every carbon fiber part meets the strictest standards for strength, durability, and surface quality.

carbon fiber parts manufacturing, CNC carbon composites, resin infusion process

Material Quality & Control

We use only certified carbon fiber, aramid, and hybrid materials, sourced from trusted suppliers. Each roll is inspected, tested, and prepared to guarantee uniform weave, resin compatibility, and optimal mechanical performance.

high-quality carbon fiber fabric, aramid hybrid composites, European carbon material supply

Precision Engineering & Fitment

Every project starts with a detailed design phase — our engineers use 3D modeling, scanning, and FEA analysis to ensure perfect geometry and performance under load. Whether it’s a one-off prototype or a production run, we deliver parts that fit flawlessly and perform reliably.

3D scanning composites, carbon fiber prototype, FEA analysis carbon structures

Proven Results & Client Trust

With years of experience across aerospace, automotive, and industrial applications, X CarbonTech is a proven partner for precision composite manufacturing. We don’t just make parts — we help our clients bring innovation to life with dependable quality and long-term collaboration.

carbon fiber manufacturer Europe, aerospace composites, custom composite parts supplier